CCTV Covered YANTIAN for Two Consecutive Days, and the Ministry of Commerce Further Highlighted It by Sharing the Report

A

A

A

缩小

加大

更大

This article is forwarded from Commerce Micro News (July 31) —

“What’s Behind China’s ‘Three Firsts’ in International Trade Amid Global Headwinds?”

In the first half of this year, China’s foreign trade delivered an impressive report card despite turbulent conditions, achieving three record-breaking milestones compared with the same period in history:

● Exports surpassed CNY13 trillion for the first time.

● The number of enterprises engaged in actual import and export exceeded 600,000 for the first time.

● The import and export value of private enterprises topped CNY12 trillion for the first time.

These “three firsts” reflect not only the resilience of China’s international trade in withstanding pressure and overcoming challenges, but also the nation’s innovative vitality and bold commitment to openness.

Behind the “Three Firsts” in International Trade: Over 72 New Shipping Services

What is driving China’s remarkable achievement of “three firsts” in international trade amid global headwinds?

No sooner had a typhoon passed than all 20 berths at Shenzhen’s Yantian Port were once again filled with giant container vessels — a scene that has become routine at the port this year.

Crystal Pang, Deputy Commercial Manager of Hutchison Ports YANTIAN said, “In the first half of this year, we welcomed 11 new international shipping services, while the number of our rail-sea service reached 33.”

Data show that in the first six months alone, China’s major ports — including Shanghai, Ningbo-Zhoushan, and Qingdao — added more than 72 new shipping services, along with over 19 new ports of destination and ports of call.

And it’s not just the ports that are expanding their reach. The New Western Land–Sea Corridor completed its first operation of railway cage cars linked with sea-going Ro-Ro vessels; the China–Laos–Thailand freight train service realised regular operation; and Chongqing launched its first scheduled freight train to Central Asia. In Chongqing, nearly 100 laptops roll off the production line every minute, and an ever-growing global trade network is helping these “Made in Chongqing” devices reach markets faster and farther.

This widening global “circle of friends” underscores the solid confidence enabling China’s international trade to forge ahead under pressure. According to the Ministry of Commerce, in the first half of this year, China set up new trade facilitation task forces with Sri Lanka and Bangladesh, bringing the total to 32, and signed new memorandums of understanding on deepening trade facilitation with Grenada, Azerbaijan, and Colombia, bringing the total to 8.

Liang Ming, Director of the Institute of International Trade Studies at the Chinese Academy of International Trade and Economic Cooperation, noted, “Our analysis shows that in the first half of the year, Belt and Road Initiative partner countries accounted for 79.4% of our export growth. In June alone, their contribution reached 98%, almost 100%. Over the same period, exports to traditional, emerging markets and more recorded positive growth, with emerging markets contributing over 80% — an exceptionally high level.”

Private Enterprises Drive Half of China’s International Trade, Innovation Fuels New Momentum

In the first half of this year, the import and export value of China’s private enterprises surpassed CNY12 trillion for the first time on record for the period, with growth outpacing the national average by 4.4%. Increasingly, high-tech products from private enterprises are heading overseas at a faster pace, aligning with international market demand through a steady stream of high-quality supply.

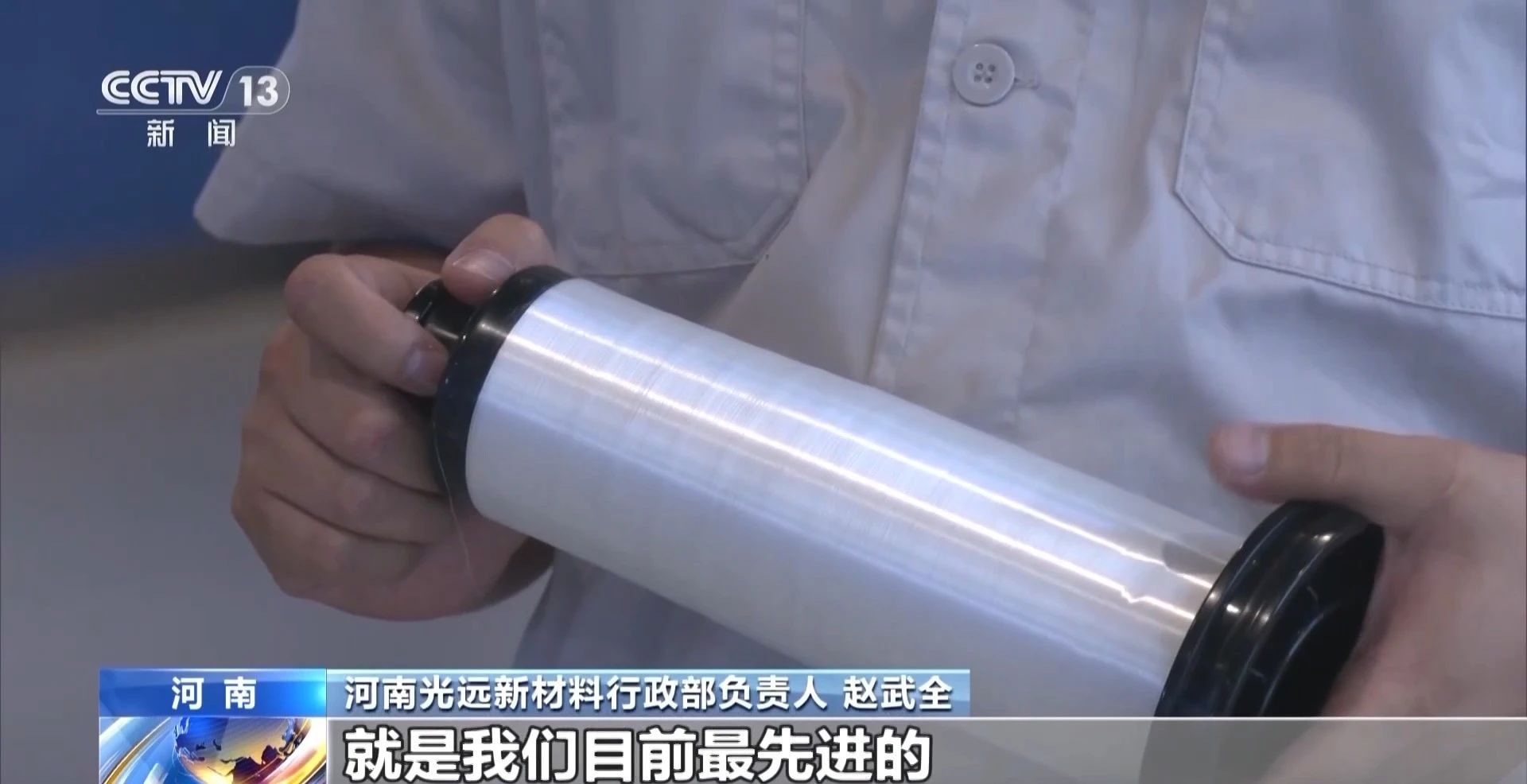

In Henan, one private enterprise has developed “electronic silk” — a critical component in integrated circuits — that secured high-end orders from Europe, the United States, Japan, and South Korea as soon as mass production began.

Zhao Wuquan, Head of the Administration Department at Henan Guangyuan New Material, explained, “This spool of yarn is our most advanced low-dielectric electronic glass fiber yarn. It takes 189 filaments combined to match the thickness of a single human hair, and it is indispensable for high-frequency, high-speed 5G transmission.”

He noted that such materials were once supplied almost exclusively by companies in Japan and the West. After eight years of R&D, the company achieved mass production of 60 million meters this year. In the first half alone, exports exceeded CNY100 million, up 70% year on year.

In Dongguan, Guangdong — where more than 90% of enterprises are privately owned — some toy makers are also experiencing an “off-season boom.” July is typically a quiet month for toy production, yet the AI toy workshop at Junou Toys was running at full capacity.

Chen Minghuan, Marketing Director of Junou Toys, said, “Agents from countries like Spain and Brazil have been placing orders one after another.”

The company has more than 20 years of OEM manufacturing experience, but profit margins in OEM have steadily declined. After a brief adjustment period, it seized opportunities in the AI sector, shifting to in-house development of AI toys — a transformation that has opened the door to new markets.

In the first half of 2025, private enterprises accounted for 57.3% of China’s total international trade. Among China’s specialised and sophisticated “little giant” enterprises with actual import and export operations, over 80% are privately owned. Exports of high-tech products from private enterprises grew by 12.5%.

Liang Ming, Director of the Institute of International Trade Studies at the Chinese Academy of International Trade and Economic Cooperation, observed: “Private enterprises are becoming a major force driving China’s export growth. Their products are more adaptable, their risk resilience is stronger, and they further enhance the resilience and competitiveness of our international trade.”

Institutional Innovation: Guiding International Trade Enterprises onto New Growth Tracks

Breaking into new markets requires more than determination — it demands breakthroughs in institutional design. From advancing cross-border e-commerce pilot zones to optimising port opening layouts, a series of policies introduced this year have been helping international trade enterprises unlock fresh opportunities.

In Lianyungang, Jiangsu Province, waste cooking oil — once shunned — is now being transformed through advanced processing into sustainable aviation fuel. As the global aviation industry accelerates toward “net-zero emissions,” bio-aviation fuel is playing an increasingly important role in driving the green, low-carbon transition while opening new avenues for export.

Yet, the journey to take this green product abroad was anything but straightforward. As a new product category, bio-aviation fuel initially lacked a mature export pathway. Manufacturers found themselves producing a world-class product with no clear route to overseas markets. To solve this, the Ministry of Commerce and other departments introduced a “white list” regulatory mechanism, allowing eligible regions to pilot exports ahead of wider adoption. In May, China’s first shipment of bio-aviation fuel was successfully exported.

He Jian, General Manager of Lianyungang Jiaao New Energy, said, “In May, we shipped our first cargo, which arrived at the customer’s port on July 14. We are now ramping up production and expect to export around 30,000 tonnes of bio-aviation fuel per month.”

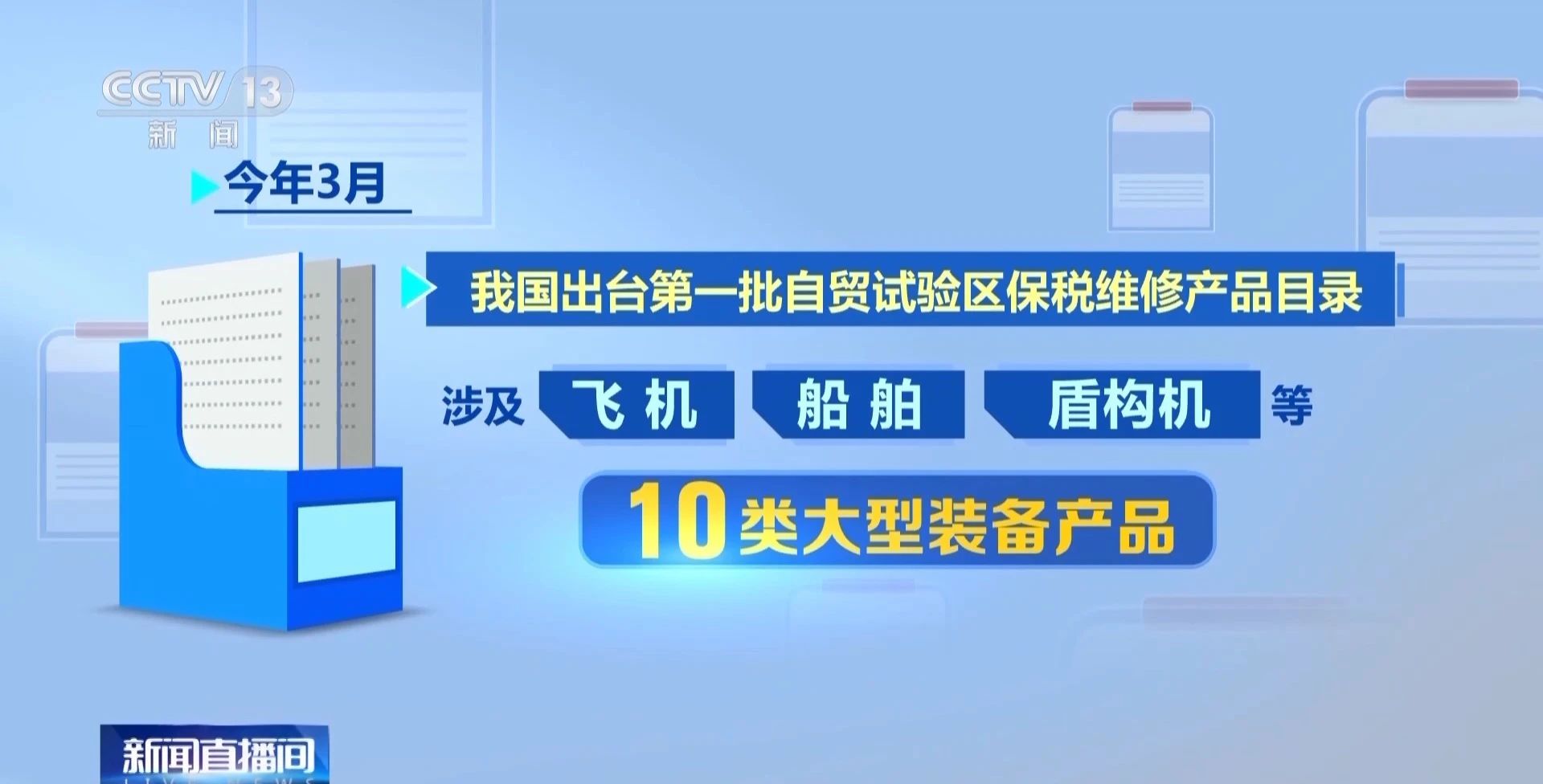

Institutional innovation is also propelling the rapid rise of another form of “invisible export” — bonded repair services. This year, the industry has expanded quickly in multiple regions. At Sichuan Services Aero-Engine Maintenance Co., Ltd. in Chengdu, engineers are busy repairing more than a dozen plane engines from overseas. Xiong Jie, Manager of the Overall Planning Department, noted: “In the first half of this year, the maintenance market surged. By the end of June, we had received 97 engines, a year-on-year increase of 25%.”

In March, China released its first catalogue of bonded repair products for pilot free trade zones, covering ten categories of large-scale equipment, including planes, ships, and tunnel boring machines. According to the Ministry of Commerce, by mid-2025, more than 280 bonded repair projects were operating across 24 provinces, autonomous regions, and municipalities.

As Xiong Jie explained, “We used to focus only on repairing high-pressure turbines in engine cores; now we’ve expanded to high-pressure compressors and plan to move into low-pressure turbines. This growth is also boosting the entire upstream and downstream supply chain.”

Source: CCTV News